Solar Panel Manufacturing Processes: Types, Production Stages, Environmental Impact, Recycling, and Future Trends.

Solar panels are a vital component of renewable energy systems, converting sunlight into electricity. Understanding the manufacturing processes of solar panels is essential for renewable energy enthusiasts. This comprehensive article covers the main aspects of solar panel manufacturing, including types, raw materials, production stages, environmental impact, recycling, and future trends.

Types of Solar Panels

Solar panels come in different types, such as monocrystalline, polycrystalline, and thin-film solar panels. Monocrystalline panels are made from a single crystal of silicon, offering high efficiency and durability. Polycrystalline panels are made from multiple crystals of silicon, making them less efficient but more affordable. Thin-film solar panels use a thin layer of semiconductor material, making them lightweight and flexible.

Raw Materials

The primary raw materials used in solar panel manufacturing are silicon, glass, and aluminum. Silicon is the main component of solar cells, while glass is used for the panels’ protective layer. Aluminum is used for the frame and backing material.

Production Stages

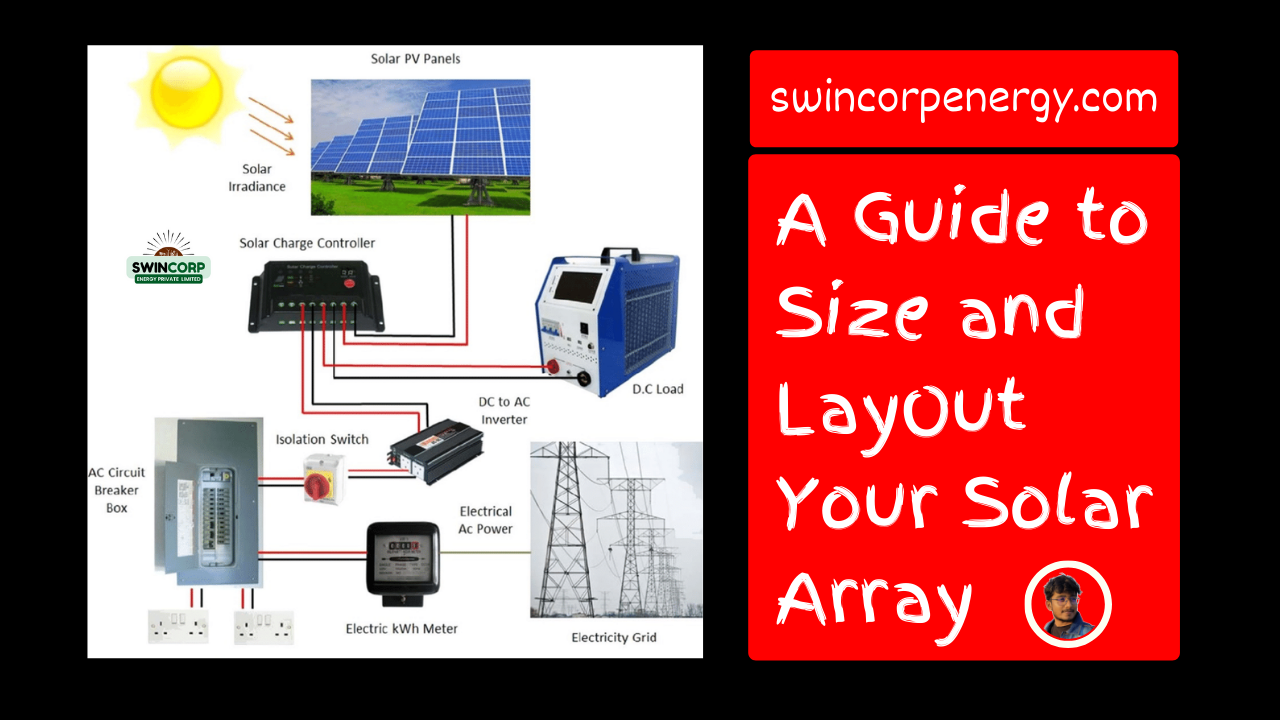

Solar panel production involves several stages, including silicon processing, wafering, cell fabrication, module assembly, and testing. The process begins with silicon processing, where raw silicon is melted and purified. Wafering involves cutting the silicon into thin slices, which are then processed into solar cells. Cell fabrication involves depositing layers of conductive materials onto the silicon wafers, followed by module assembly, where the cells are connected and encapsulated in a protective layer.

The stages involved in solar panel production are:

- Silicon processing: The raw silicon is melted and purified to create high-purity silicon ingots or wafers.

- Wafering: The silicon ingots or wafers are cut into thin slices, which are then processed into solar cells.

- Cell fabrication: A series of processes are performed on the silicon wafers to create solar cells, including depositing layers of conductive materials.

- Module assembly: The solar cells are connected and encapsulated in a protective layer, forming a solar module or panel.

- Testing: The solar panels are tested for performance and durability before being shipped to customers.

- Installation: The solar panels are installed on rooftops, solar farms, or other structures to generate electricity.

- Maintenance and monitoring: Regular maintenance and monitoring are essential to ensure the solar panels continue to operate efficiently.

- Recycling: At the end of their useful life, solar panels can be recycled to recover valuable materials, such as silicon, glass, and aluminium.

Environmental Impact

Solar panel manufacturing has an environmental impact, primarily due to the energy-intensive process of producing silicon. However, the overall environmental impact of solar panels is significantly lower than that of fossil fuel-based energy sources. The use of solar panels reduces greenhouse gas emissions and contributes to a more sustainable energy future.

Recycling Process

Recycling solar panels is an important aspect of their life cycle. At the end of their useful life, solar panels can be recycled to recover valuable materials, such as silicon, glass, and aluminum. The recycling process involves disassembling the panels, separating the components, and processing them for reuse.

Future Trends

Future trends in solar panel manufacturing include the development of more efficient and affordable solar cells, such as perovskite solar cells. Additionally, advancements in recycling technology will enable the recovery of more materials from end-of-life solar panels. As the demand for renewable energy grows, solar panel manufacturing will continue to evolve to meet these needs.

Conclusion

Understanding the manufacturing processes of solar panels is crucial for renewable energy enthusiasts. This comprehensive article has covered the main aspects of solar panel manufacturing, including types, raw materials, production stages, environmental impact, recycling, and future trends. As the world transitions to a more sustainable energy future, solar panels will play a significant role, and understanding their manufacturing processes will help us make the most of this clean and abundant energy source.

Join whatsApp Channel

keys: solar panel manufacturing, solar cell manufacturing, solar panel production process, solar cell types, photovoltaic manufacturing, solar panel materials, silicon wafer production, solar cell efficiency, solar panel assembly, thin film solar cells, monocrystalline silicon, multi-crystalline silicon, solar panel encapsulation, solar panel testing, solar panel recycling, solar cell doping, solar panel grid connection, solar panel inverter, solar energy generation, sustainable energy production

Maruti Brezza CNG: Mileage, Review, Features - Swincorp Energy

[…] Solar panel manufacturing processes […]

Top 5 Best Solar Lights for Your Home | Swincorp Energy - Swincorp Energy

[…] Solar panel manufacturing processes […]

Tata Punch EV: On Road Price, Range, Review - Swincorp Energy

[…] Solar panel manufacturing processes […]